Allis Roller offers a wide variety of machining services through our arsenal of cutting-edge, high-quality equipment and machinery. For those customers unable to visit our facility for themselves, we have provided a transparent list of equipment specs and services below.

Services and Equipment Specs

Select a heading to learn more.

Machining

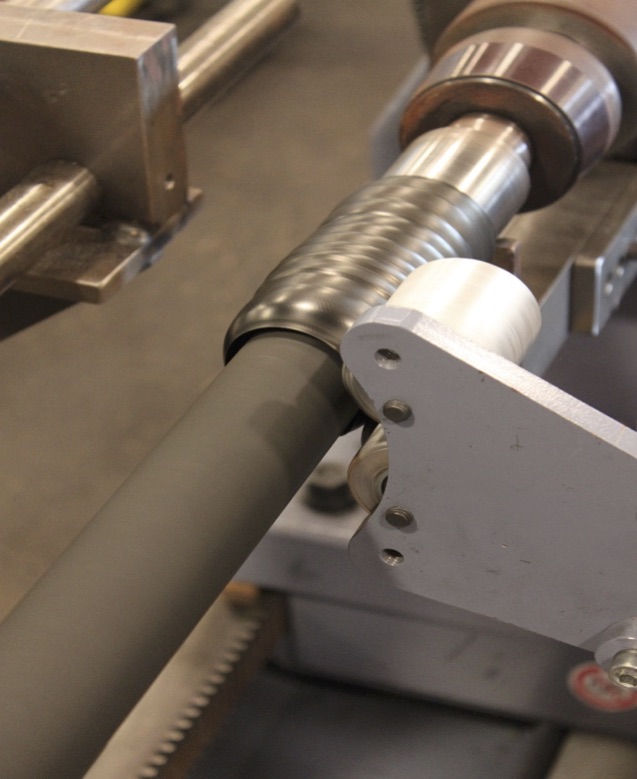

Grinding – cylindrical

Cylindrical Grinding is used for very close tolerance parts, and provides a smooth surface finish. Our cylindrical grinding machine is able to hold a max diameter of 16” X 40” long.

- 1 – 1999 Toyoda CNC 90⁰ head – 16" max dia. x 40" long

- 1 – 1995 Toyoda CNC 30⁰ head – 11.8” max dia. x 40.0” long – auto sizer

- 1 – 1996 Toyoda CNC 90⁰ head – 11.8” max dia. x 40.0” long – auto sizer

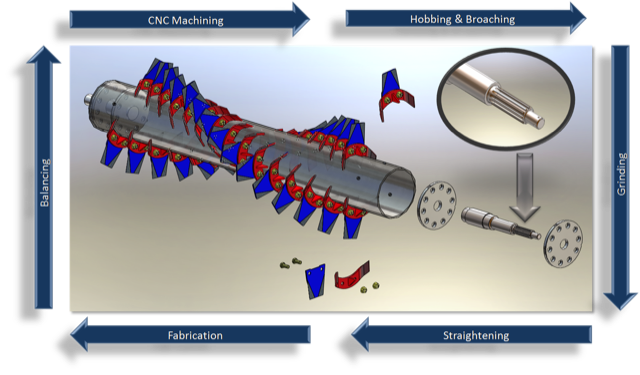

Hobbing

Hobbing and Broaching allows us to add keyways, as well as sprockets and gears, to many round bar application.

- 1 – Barber-Coleman Hob – 16-36 rebuilt in 2012

- 1 – Barber-Coleman Hobs – 10-20

- 1 – Barber-Coleman Hob – 16-56

- 1 – LaPoint Broach 40,000 lb x 72" stroke

- 1 – LaPoint Broach 40,000 lb x 64" stroke

CNC Turning – 16 machines

CNC Turning provides close tolerance for shaft work, tubes, roller work, and virtually any round component. Our CNC turning equipment can turn materials up to 28” diameter X 115” long.

- 1 – 2017 – '06 Romi flat bed CNC lathe 12" chuck – 14.2 turn dia x 115" long

- 1 – 2017 – '07 Ingersol flat bed CNC lathe 12" chuck – 13" turn dia x 75 long

- 1 – 2013 Samsung SL-45BBM -6.5" bar cap. – live tool – 24" chuck – 28" turn dia x 85" long – 9.6" dia auto steady rest

- 1 – 2013 Wia L300C – 3.5 bar cap. – 12" chuck – 22" turn dia x 28" long

- 1 – 2012 Samsung SL-35 – 4.6” bar cap. – 15” chuck – 16.5" turn dia x 56.0” long

- 1 – 2012 Fryer – 6" bar cap. – dual 20" chucks – 30" turn dia x 115" long – 12.2" dia auto steady rest

- 1 – 2011 Samsung SL-45 – 4.6" bar cap. – 18" chuck – 28" turn dia x 85" long – 9.6" dia auto steady rest

- 1 – 2011 Yama Seiki GS260M – 2.55" bar cap. – 10" chuck – live tooling – prepped for bar feed work

- 1 – 2010 ToolMex Flatbed – 3.5 bar cap. – 12" chuck – 28" turn dia x 115" long – manual steady & follower rests

- 1 – 2009 Kia SKT-400 – 3.5" bar capacity – live tool – 15" chuck – 25.0" turn dia x 47" long

- 1 – 2008 Yama Seiki GA2600 – 2" bar capacity – 10" chuck – 14" turn dia x 24" long

- 1 – 2007- Kia SKT 300 – 3.5" bar capacity – 12" chuck – 22.0" turn dia x 28.0" long

- 1 – 2006 Kia SKT 25 – 3" bar capacity – 12" chuck – 19.7" turn dia x 28.0" long

- 1 – 2005 Mori Seiki NL-3000 – 4" bar capacity – live tooling – 15" chuck – 16.5" turn dia x 26.0" long

- 1 – 1997 Mori Seiki SL-200MC – 2" bar capacity – live tooling – 8" chuck – 15.3" turn dia x 20.0" long

- 1 – 1996 Mori Seiki SL-300 – 2.9" bar capacity – 12" chuck – 16.3" turn dia x 28.3" long

CNC Milling – 5 machines

CNC Milling provides close tolerance vertical cutting with precision drilling and tapping capabilities

- 1 – 2013 Wia F500VM VMC – 43.3 x 21.7 x 20.5 – Cat 40 taper – 1.5 second tool to tool

- 1 – 2012 Wia F500-50 VMC – 43.3 x 20.1 x 25.0 – Cat 50 taper – 4 second tool to tool

- 1 – 2010 Mazak 510C-II VMC – 43.1 x 20.0 x 20.0 – 2 pallet shuttle table – Cat 40 taper – 1.3 second tool to tool

- 1 – 2005 Mazak 510C VMC – 43.1 x 20.0 x 20.0 – 2 pallet shuttle Cat 40 taper – 1.6 seconds tool to tool

- 1 – 1995 Mazak V515 VMC – 41.3” x 20.0” x 20.0” – 2 pallet shuttle table 51.1” x 21.6” – Cat 50 taper – 60 tool magazine

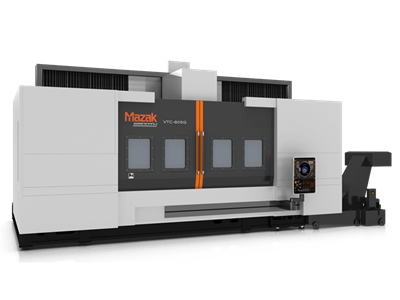

Vertical Machining Center with Mazatrol Smoothing Control

Our new MAZAK VTC-805G Vertical Machining Center with smooth technology features a powerful 50 taper spindle, full traveling column design and fixed table for machining extremely long and heavy workpieces. The machine has a table partition so the table can be transformed into two separate work areas for an overall reduction in cycle times. The turret-style magazine has 10 four-tool-position units for tooling versatility with different workpiece types and reduced job setup times.

Part size capability:

Max. part length: 118 inches

Max. part width: 32.3 inches

Max. part height: 28.3 inches

Horizontal Machining Center with Mazatrol Smoothing Control

Our new MAZAK horizontal machining center Nexus 6800 provides unsurpassed performance, precision, and reliability for high-volume large heavy part operations.

The world-class HCN-6800 horizontal machining center combines advanced technology with high performance and high productivity for achieving maximum performance when working with virtually any type of material. The machine features spacious work envelope and pallet size, twin pallets for improved productivity, as well as a fast rapid traverse speed and rigid, reliable 50 taper spindles.

The machine provides fast, efficient and versatile machining of a wide variety of materials from steels to nonferrous metals.

Part size capability:

Max. workpiece length/width: 41.34 in

Max. workpiece height: 51.18 in

Pallet dimension: 24.80 in square

Fabrication

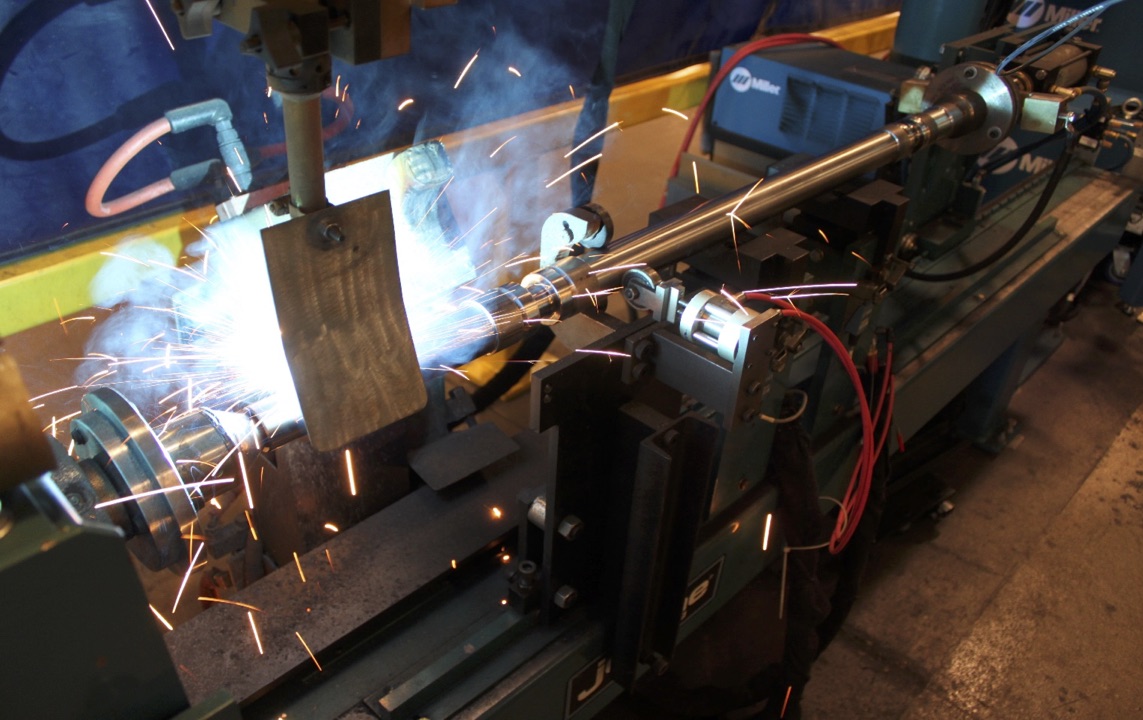

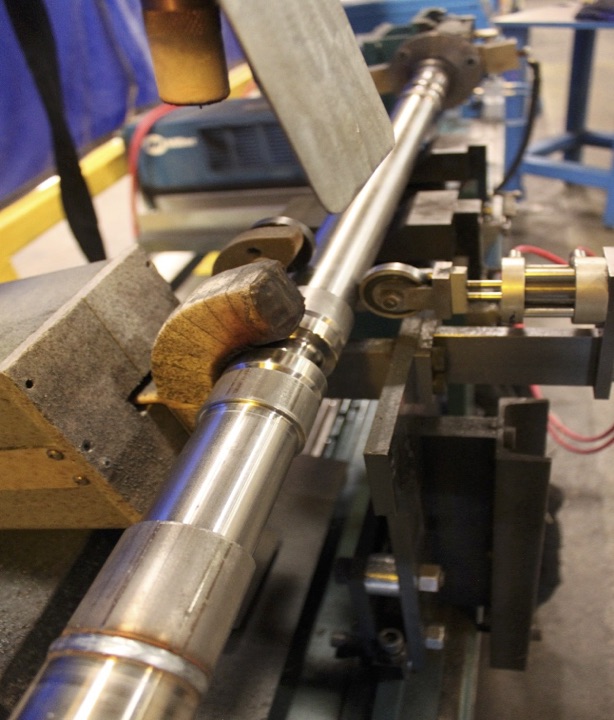

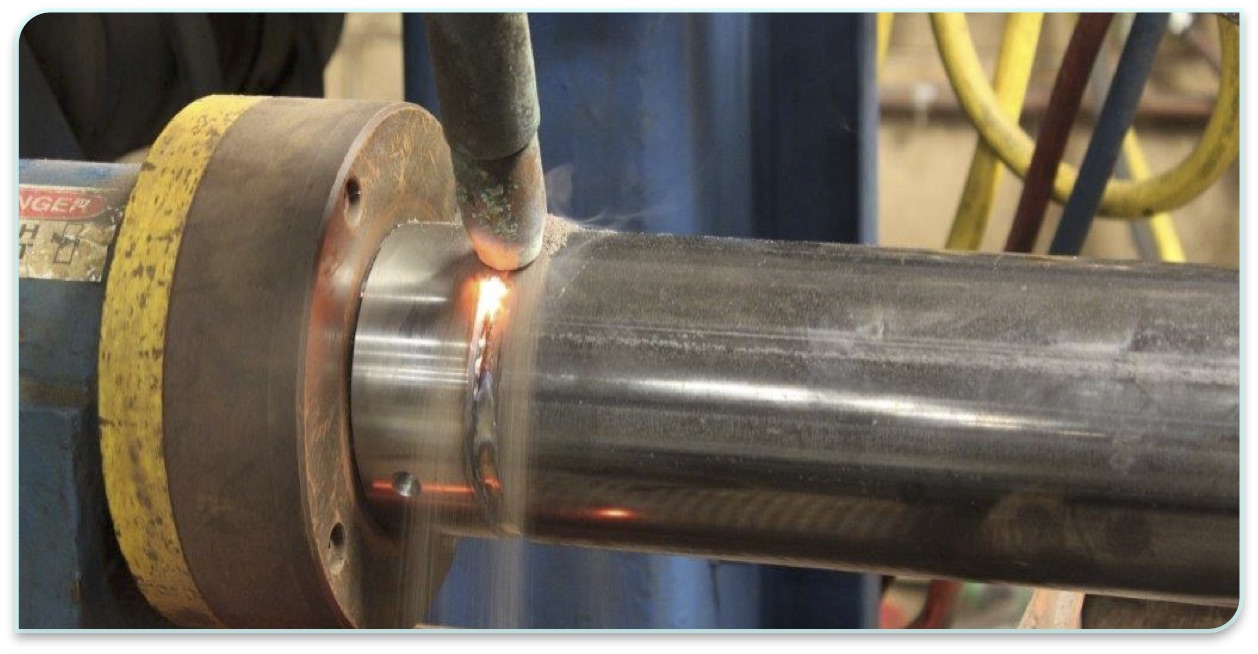

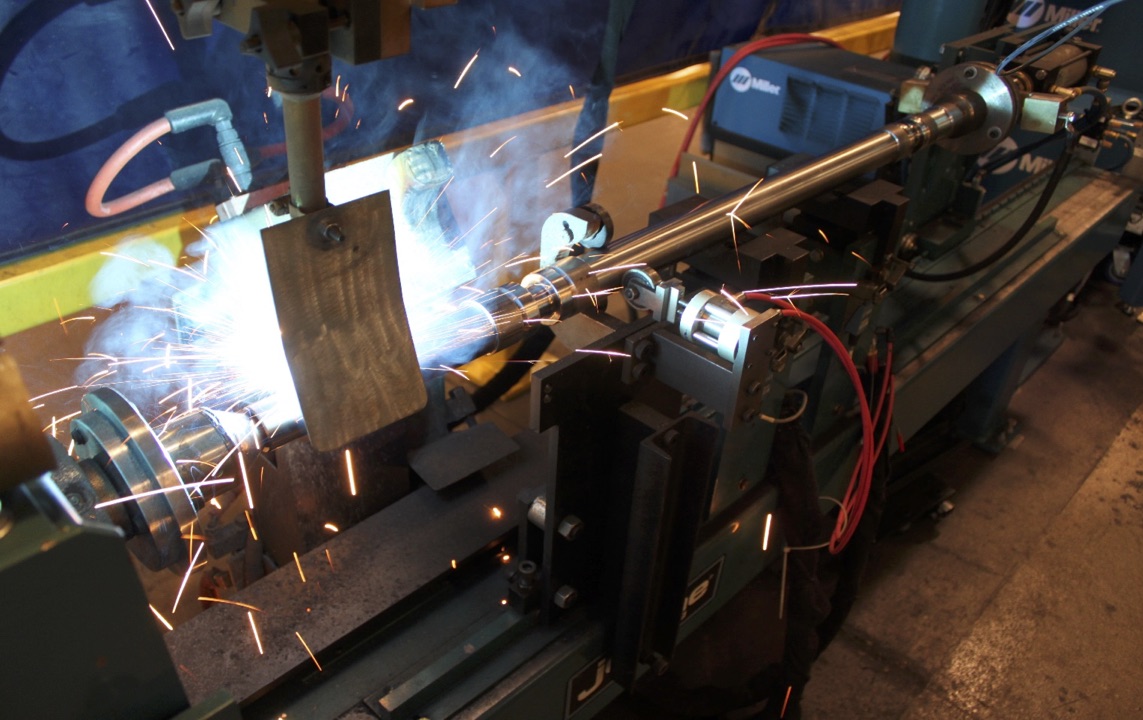

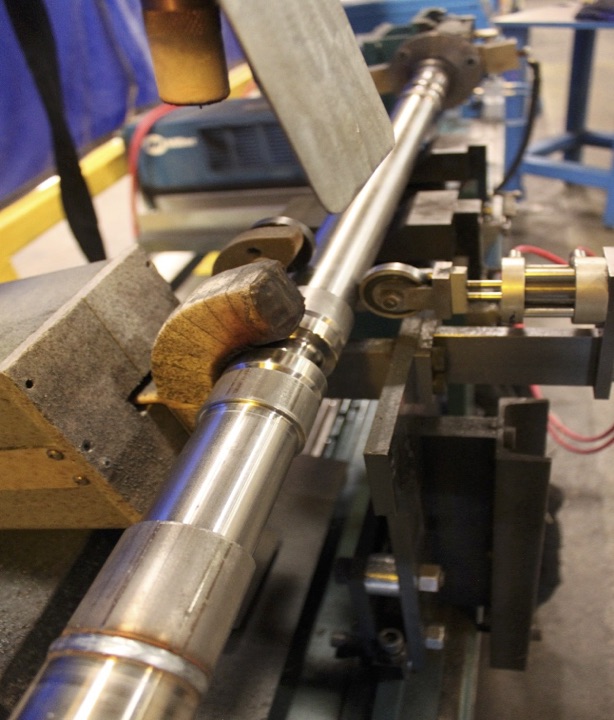

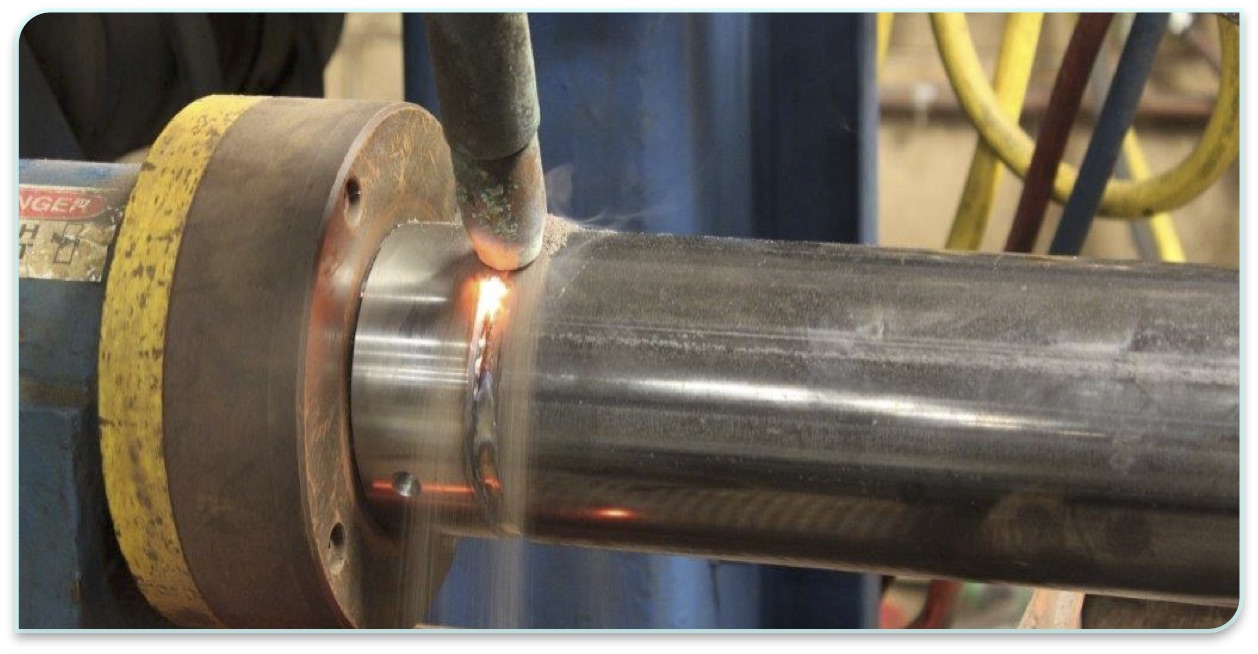

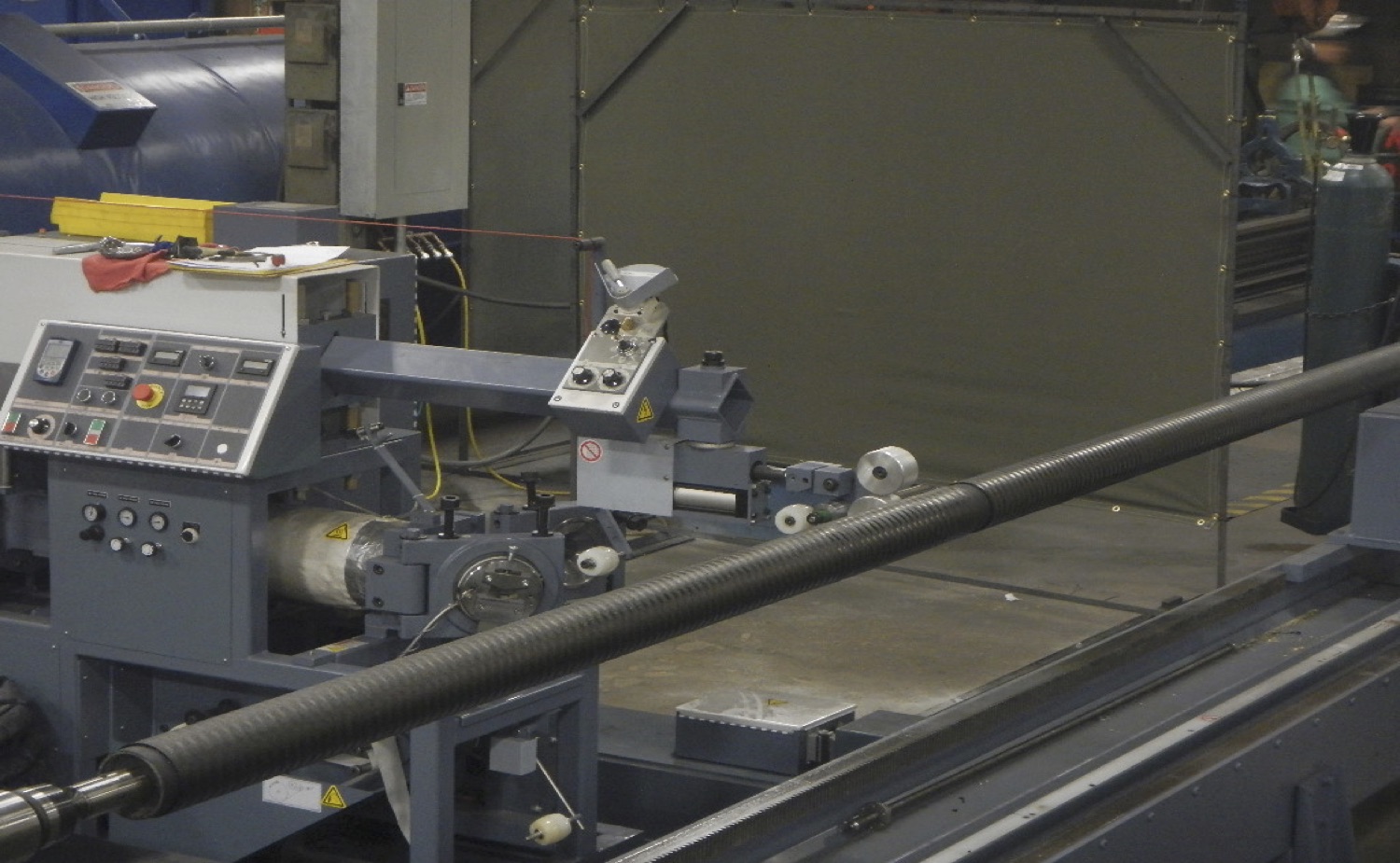

Robotic Welders

- 1 – 2016 Miller/Jetline Robotic 2 axis MIG – Tube Welding Lathe with Miller 450-DI welder

- 1 – 1999 Robotic 2 axis Sub Arc – Tube Welding Lathe with Miller 650 welder

Additional Welding – 29 total welders

Allis Roller employs twenty-nine total additional welders working in conjunction with two robotic welders. Welding provides the assembly and final fabrication work needed for a variety of roller and non-roller applications, including fan blades.

- 2- Miller XMT304 with 22A Feeder

- 2- Miller XMT350 with 24A feeder

- 2- Miller XMT 450 with 5-74 mpa feeder

- 9 – Miller 252 welders

- 9 -Miller 450 & 452 series welders

- 5- Miller 350P & 350MPA welders

- 1 – Aluminum TIG welding gun for above welders

- 3 – welding lathes – dual chucks/collets – with steady rest centering supports

- 1 – Jetline – shaft & flange power weld head with chuck

- Various rotational weld positioners up to 17 feet long

- 1 – 900 degree preheat oven – 75 cubic foot capacity

Allis Roller provides all the necessary secondary operations like drilling, straightening, manual turning, and balancing in house.

- Drilling

- 1 – double end tube drilling machine

- 1 – special purpose drilling and straightening machine for tubes to 17 ft long

- Turning

- 1 – manual turret lathe – 8" chuck

- 3 – large manual lathes up to 16" dia. x 115" long

- Straightening

- 2 – tube/bar hydraulic straightening machines – max 200" table length & 3 pull positions

- Balancing

- 4 – horizontal dynamic balancing machines up to 24" dia. x 108" long

- 1 – vertical dynamic balancing machine for short parts to 15" long

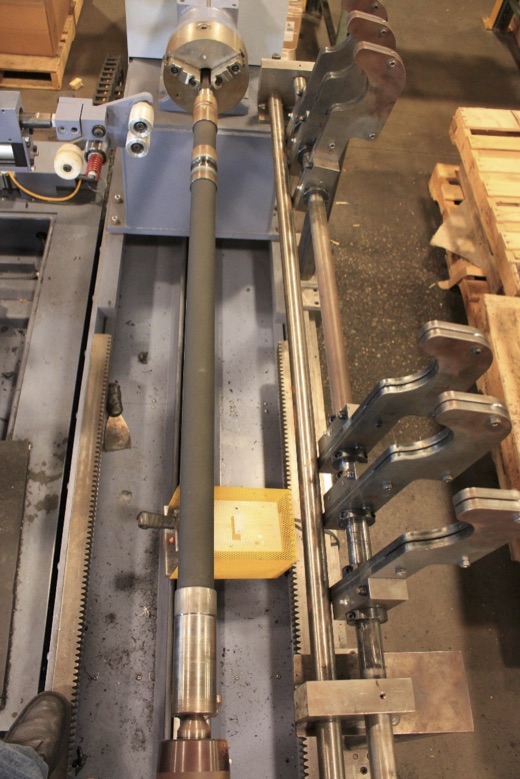

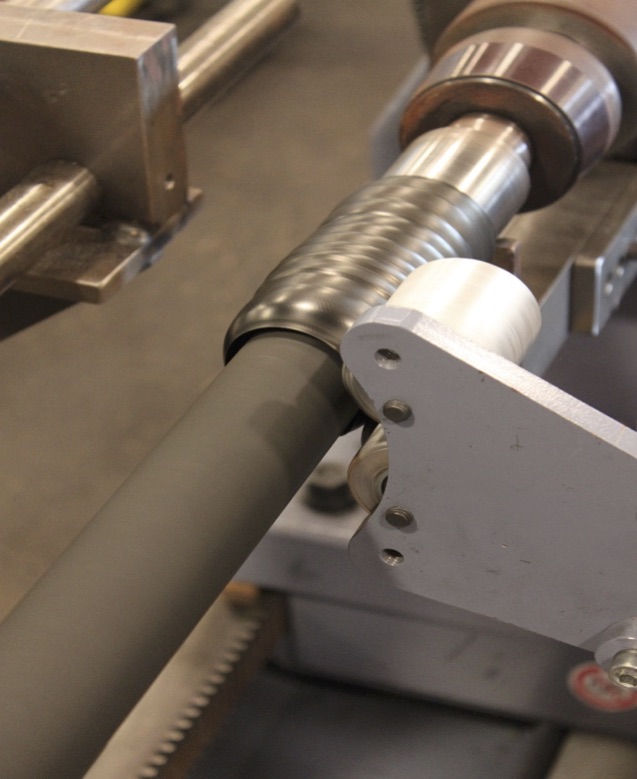

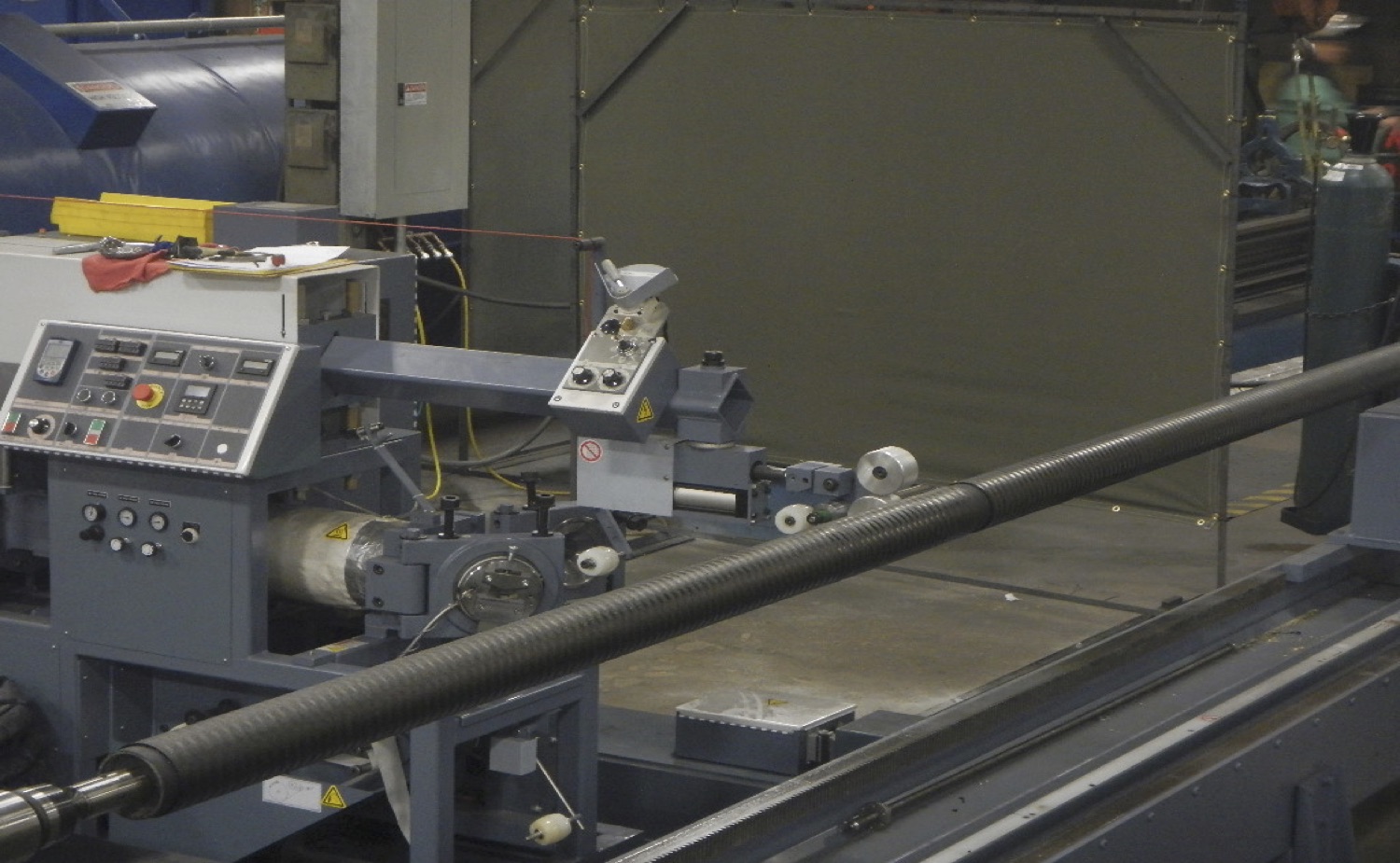

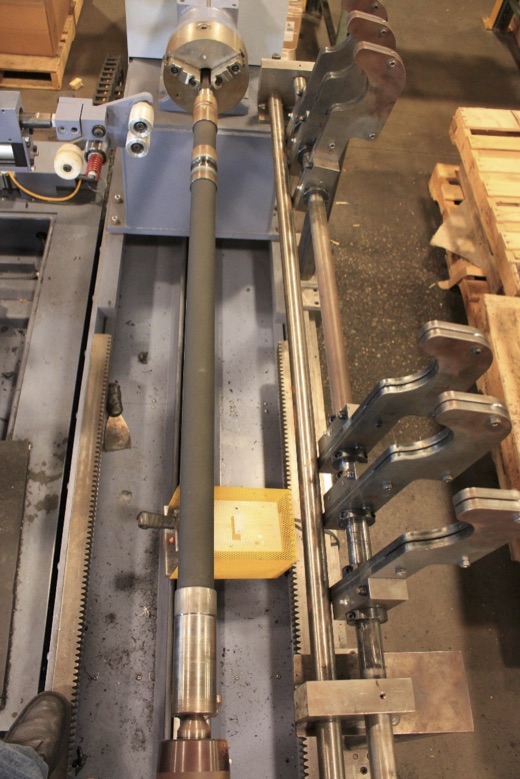

SBR Rubber Roller Processing Line

Our SBR Rubber Roller Processing line provides two downdraft tables for primer and adhesive applications. Allis Roller utilizes Remco SBR strip builders and two autoclaves along with a 32” diameter X 20 foot long grinding and sanding lathe.

- 1 – 2013 – 20 ft Downdraft Table with automated 17' carousel for primer and adhesive application

- 1 – 2017 – 20 ft Downdraft Table for primer and adhesive application

- 1 – 2013 Remco SBR Strip builder – 32" dia x 24 foot long

- 1 – 2016 Remco SBR Strip builder – 32" dia x 12 foot long

- 1 – 2013 Autoclave – 60" dia x 22 foot long for vulcanizing

- 1 – 2017 Autoclave – 60" dia x 22 foot long for vulcanizing

- 1 – 32" dia x 20 foot long grinding/sanding lathe

Assembly

Allis Roller provides assembly services for various rollers and their components. The technology we employ assembles and fits with our CNC controlled bearing press to coincide with other hydraulic horizontal presses for assemblies that match print requirements.

- 1- 2017 Promess CNC controlled Bearing press – to measure minimum press force requirements

- Various hand, pneumatic and hydraulic presses

- 1 – 30 ton hydraulic horizontal press – 120" part capacity – 60" stroke

- 1 – 20 ton hydraulic horizontal press – 110" part capacity – 60" stroke

- Manual lathe – 24" dia. x 120" long

- 5 – deep freeze freezers for header to tube assembly

Quality

Allis Roller utilizes a climate controlled quality lab for precision checking and recording of work done on the shop floor. Additionally, we provide an outside service with a portable six foot faro arm allowing 12 foot measurements to be taken anywhere. Calibrated measuring equipment is located throughout the Shop for checking and recording purposes. All equipment is calibrated annually.

- 1- 2015 – 6 foot Faro Arm allows 12 foot measurements – portable can measure anywhere

- 1 – Starrett CMM – 25" x 25" x 22" – Renishaw probe – PC-DMIS

- 1 – Wilson Hardness tester

- 1 – Tesa M900 (36") programmable height stand

- 1 – Tesa M600 (24") programmable height stand

- 1 – master 81 piece set ceramic Gage Block set – calibration only

- 3 – steel Gage Block sets

- 3 – Mitutoyo centers – up to 48" long

- Various – granite surface plates up to 40" x 100" long

- Various – micrometers, calipers, indicators

Tool Room

The Allis Roller Tool Room assists our processes by providing fixtures for many of the production operations. With surface grinders and manual bridgeport mills, Allis-Rollers journeyman toolmakers sharpen the cutting tools and help with secondary operations. Though automated machining is vital to our system, the manual equipment kept in our Tool Room allows us to also take on unique or small-run jobs.

- 1 – manual lathe with thread making capability

- 2 – manual Bridgeport mills w/DRO

- Various – Hob, drill & cutter grinding/sharpening equipment

- 1 – Surface grinder – wet – 12" x 28" magnet

- 1 – Surface grinder – 6" x 16" magnet

- 1 – Weld fab/fitup table

Engineering

In addition to our machining staff, the Allis Roller team includes four engineers with a combined 150 years’ experience in manufacturing. Their experience and engineering skills provide our customers with additional cost savings and oversight on projects, which helps to ensure quality and longevity of the parts we produce. Allis Roller utilizes Solidworks 3D design software, Gibbs Cam Programing software, & Draftsight 2D software to facilitate the engineering process.

- 4 – Solidworks 3D design software

- Four engineers with over 150 years in Manufacturing – over 130 in Manufacturing Engineering

- Gibbs Cam programing software – 2 – lathe and 2 – mill

- Draftsight 2D software

- MRP – Epicor 9 – with EDI capability

- Microsoft Office Suite

- Microsoft Project

- Adobe Acrobat Professional