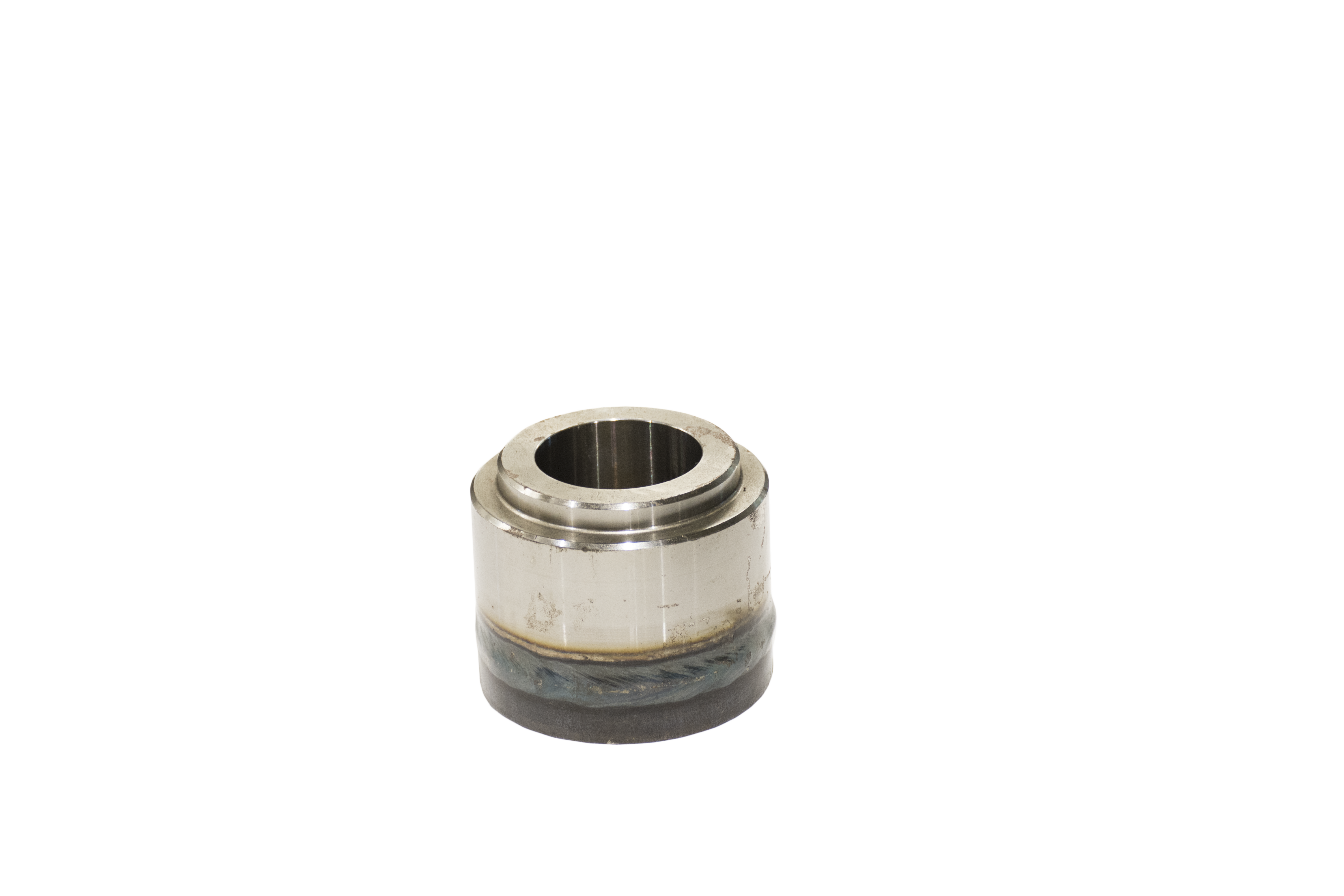

The quality of our welding work speaks for itself, which is why multinational manufacturers consistently rely on Allis Roller’s industry-leading welding services.

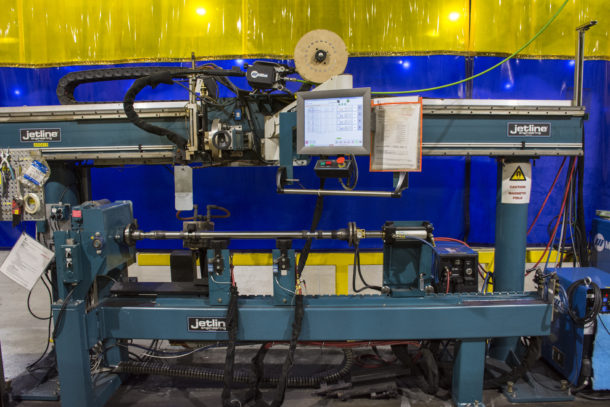

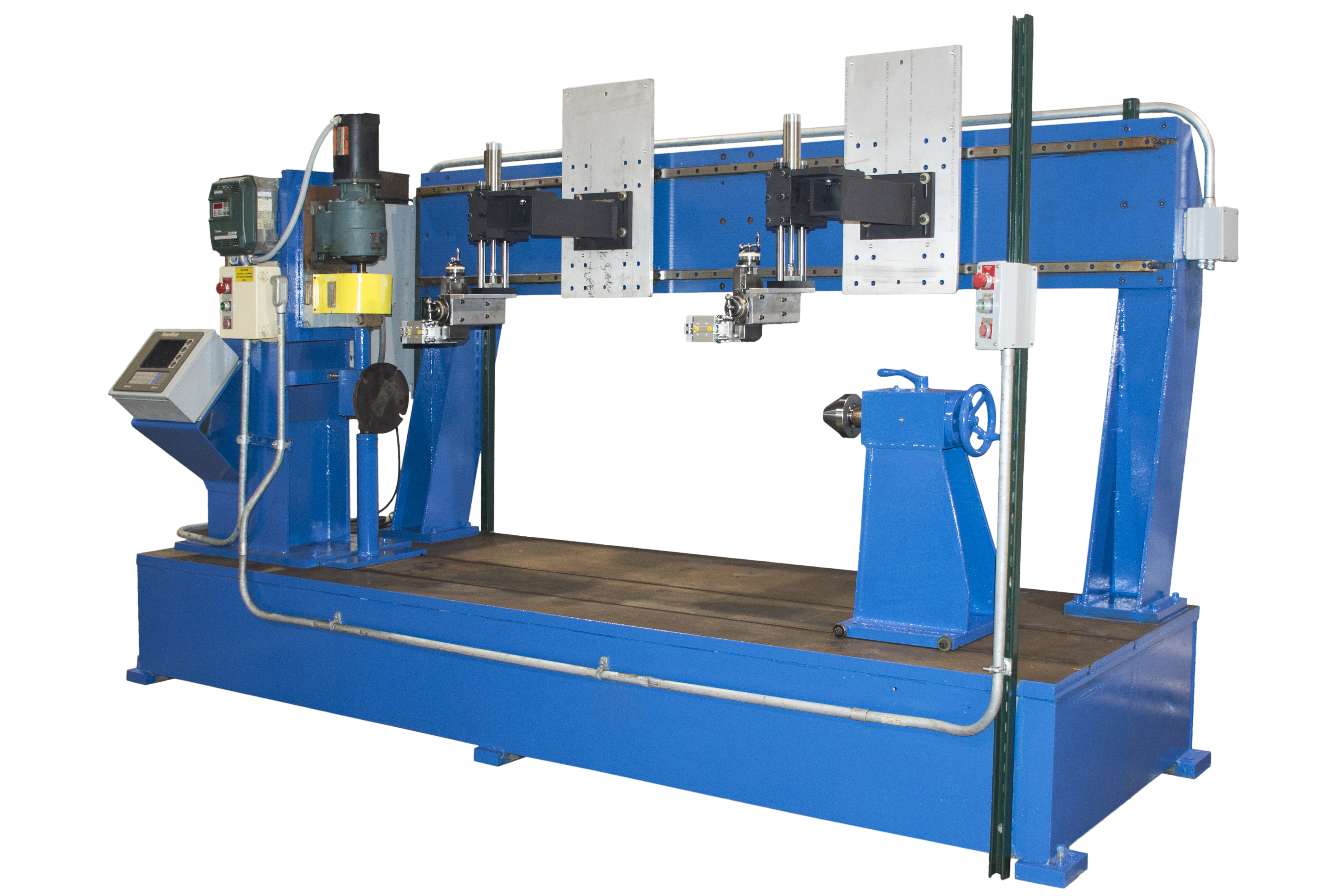

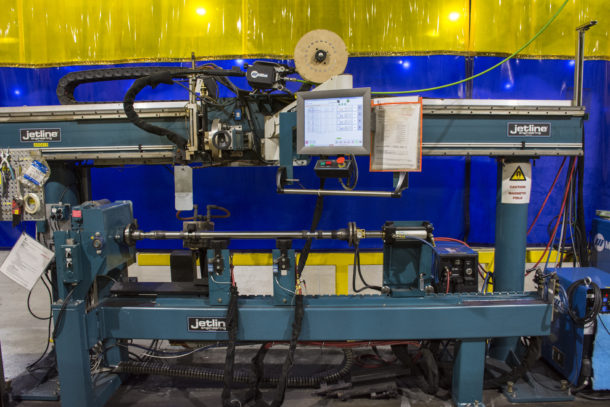

The Jetline Automated Welder

Allis Roller’s Jetline Automated Welder has the ability to precisely control pre-heat and welding parameters, making the weld process consistent from weld joint to weld joint. Without sacrificing quality or accuracy, the Jetline Automated Welder is capable of welding over 40,000 rollers per year, and a theoretically unlimited number of weld joints on a single roller. For complex rollers requiring quick turnaround, the Jetline gets the jobs done.

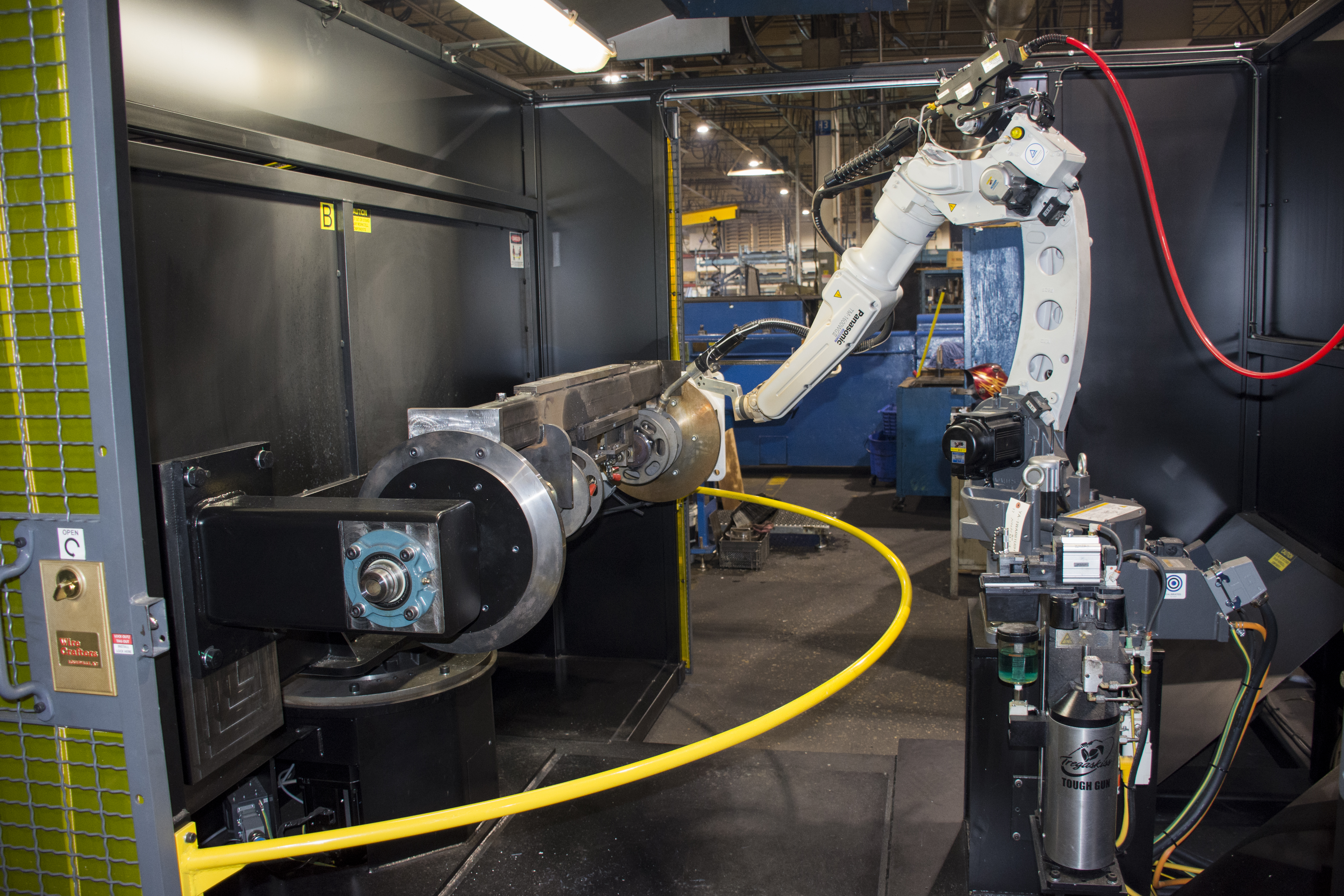

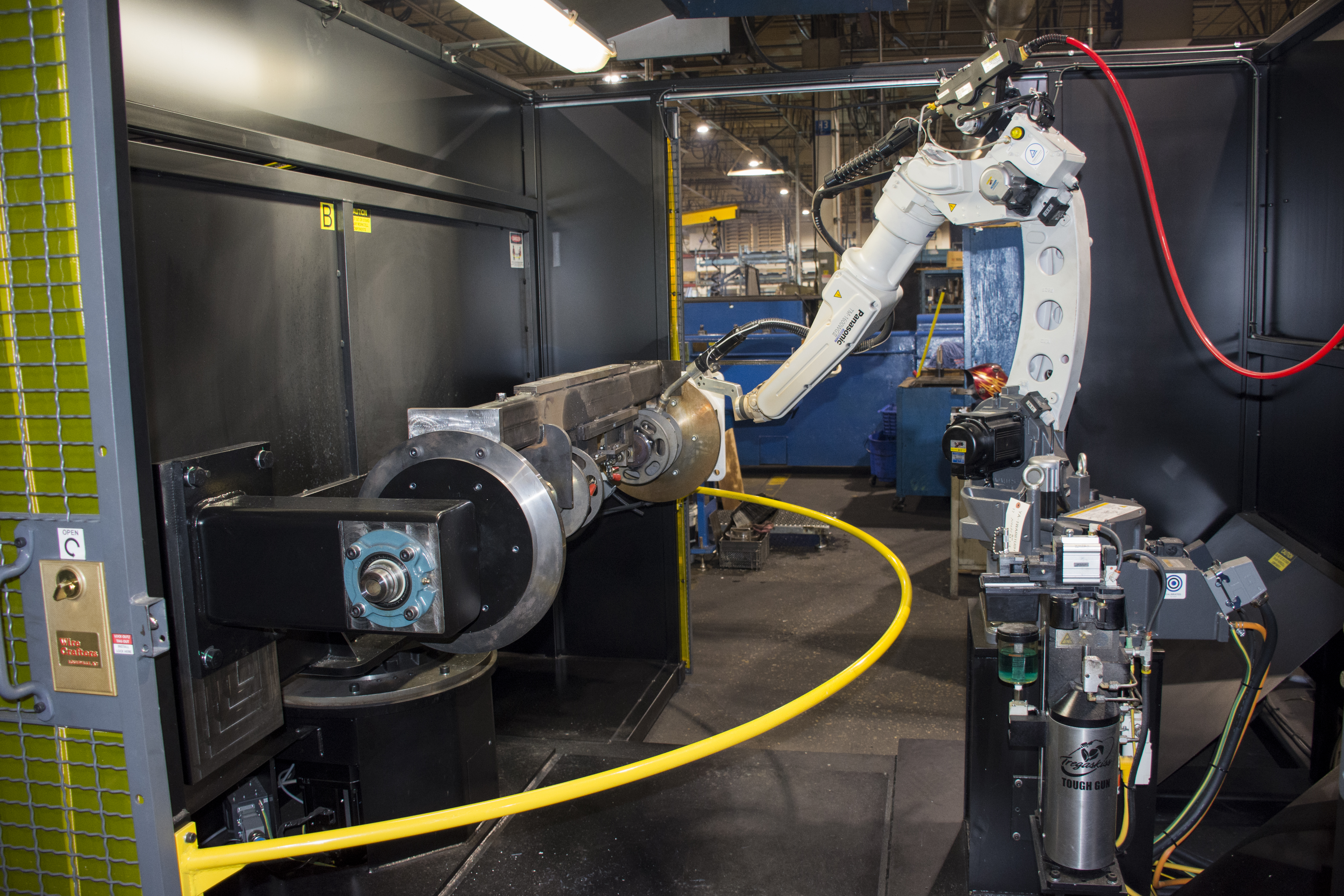

The Miller Robotic Welder

The Miller Robotic Welder is a cutting-edge welding machine that enables volume welding work to be accomplished by a single technician using rotating fixture cluster technology. Like its cousin, the Jetline Automated Welder, the Miller/Panasonic can weld multiple parts at once with impeccable accuracy. With the Miller, Allis Roller is able to quickly produce precision welds, while reducing turnaround and simultaneously improving the quality of the final product.

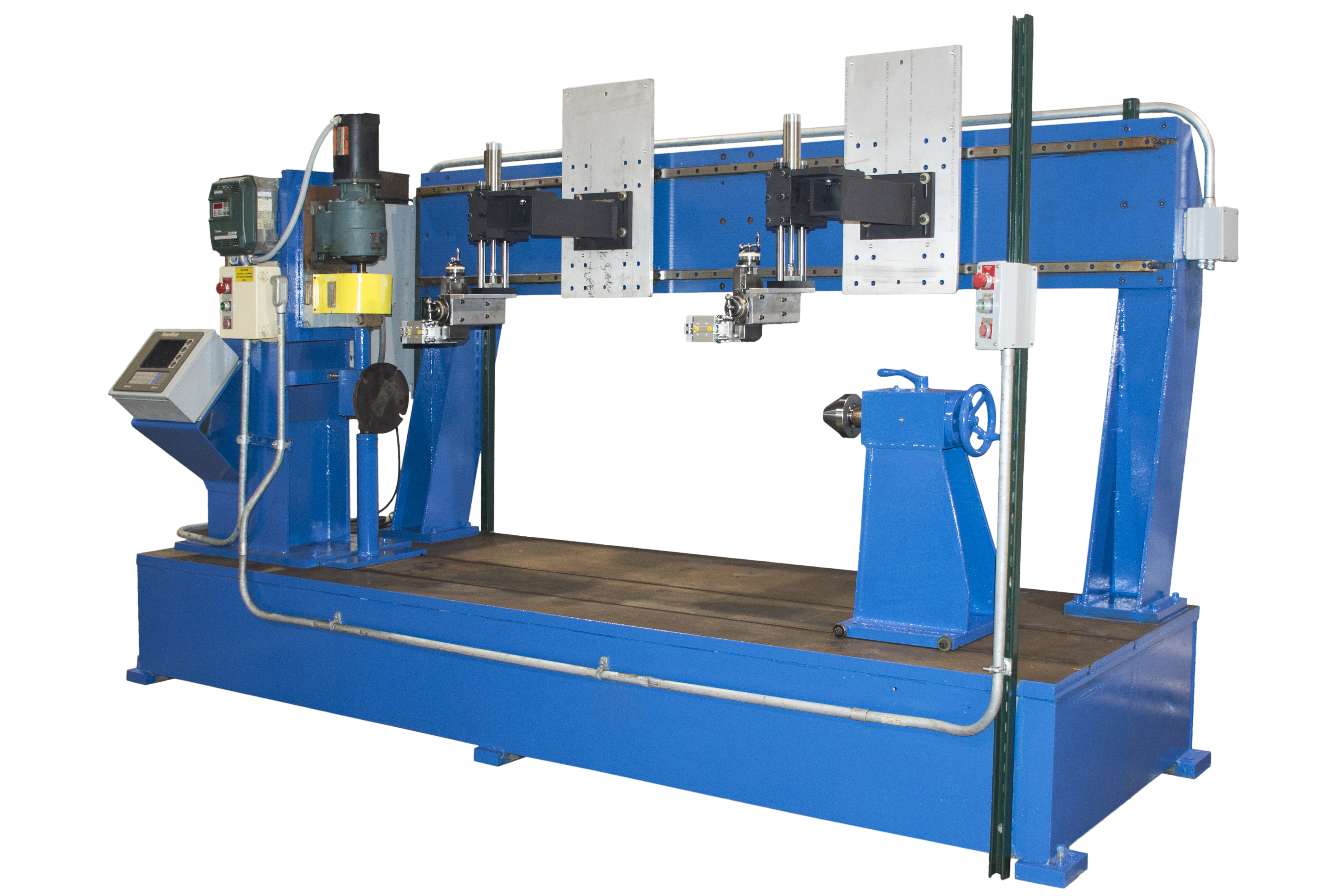

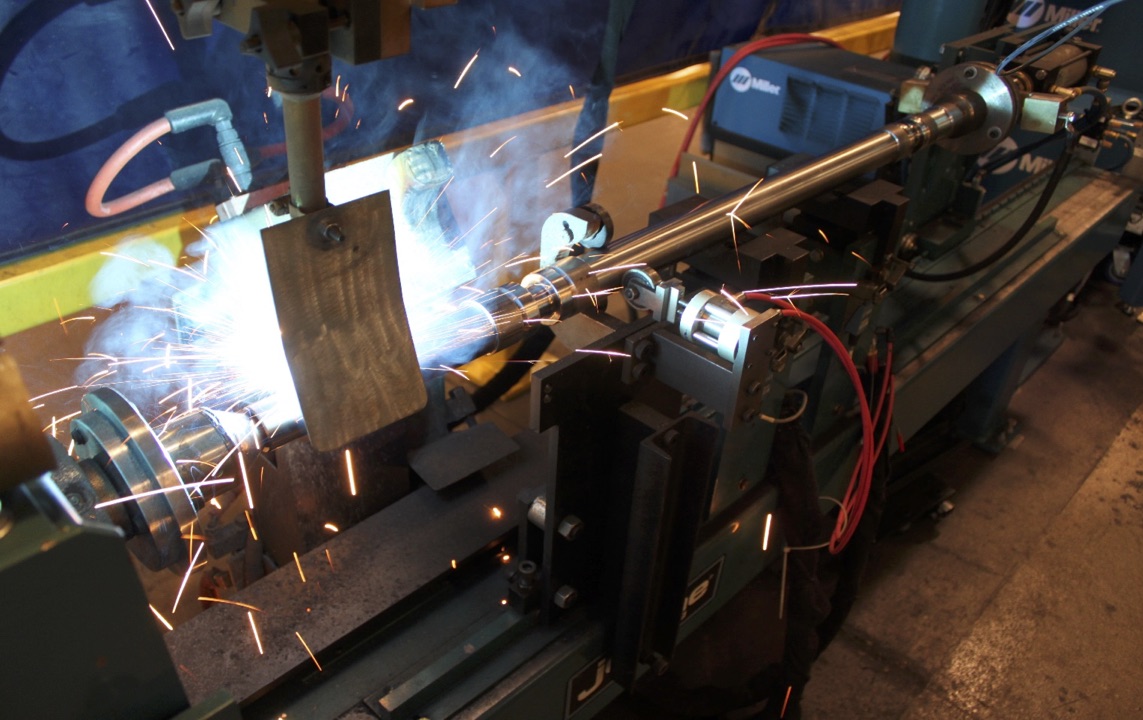

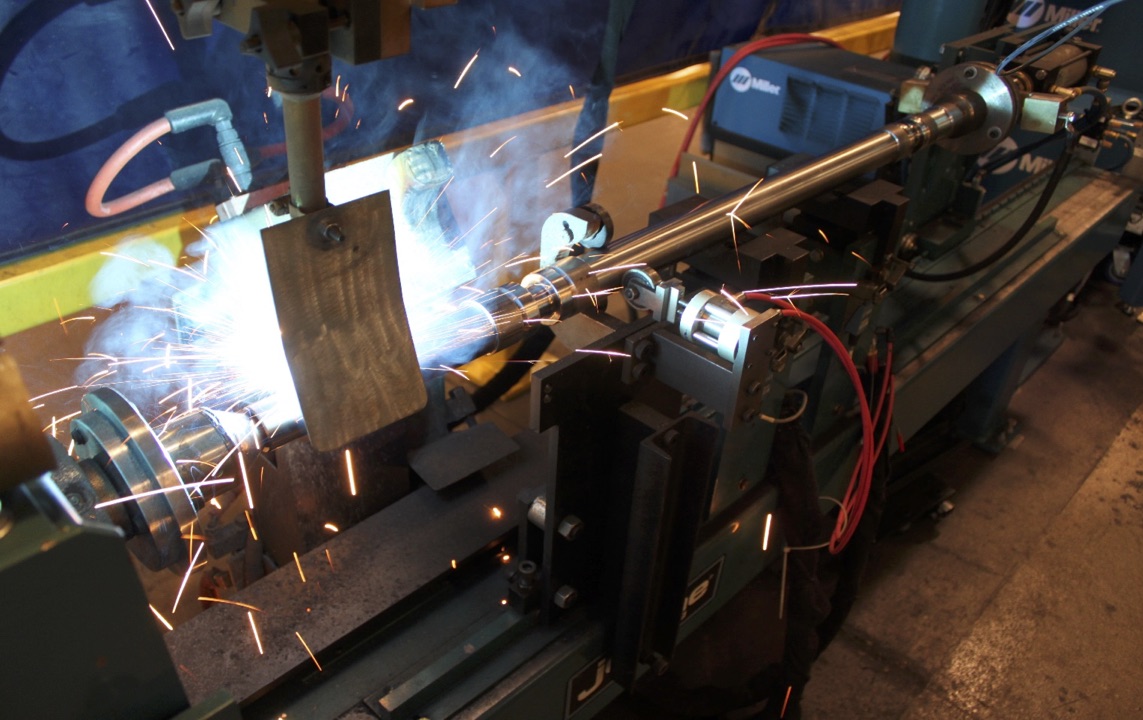

Submerged Arc Welding

Submerged Arc Welding (SAW) is a uniquely safe and consistent welding method first developed in early 1900s. For the majority of the precision machining work done at Allis Roller, we deploy the latest automated equipment operated by our skilled technicians, and our application of modern SAW technique is no different. During an automated SAW process, a CNC program rotates the part at a specified speed, while controlling the heat and speed of the weld to ensure optimum quality and consistency of the part. As a result, large amounts of metal can be safely deposited in a short amount of time, which makes automated SAW an excellent choice for welding heavy pieces of equipment.

Capabilities Include:

Welding of Steel, Stainless, and Aluminum

Robotic Welders

- 1 – 2016 Miller/Jetline Robotic 2 axis MIG – Tube Welding Lathe with Miller 450-DI welder

- 1 – 1999 Robotic 2 axis Sub Arc – Tube Welding Lathe with Miller 650 welder

Additional Welding – 29 total welders

Allis Roller employs twenty-nine total additional welders working in conjunction with two robotic welders.

- 2- Miller XMT304 with 22A Feeder

- 2- Miller XMT350 with 24A feeder

- 2- Miller XMT 450 with 5-74 mpa feeder

- 9 – Miller 252 welders

- 9 -Miller 450 & 452 series welders

- 5- Miller 350P & 350MPA welders

- 1 – Aluminum TIG welding gun for above welders

- 3 – welding lathes – dual chucks/collets – with steady rest centering supports

- 1 – Jetline – shaft & flange power weld head with chuck

- Various rotational weld positioners up to 17 feet long

- 1 – 900 degree preheat oven – 75 cubic foot capacity